Rodhini Safety Pvt. Ltd. customercare@rodhini.com

Mobile: 9495009933

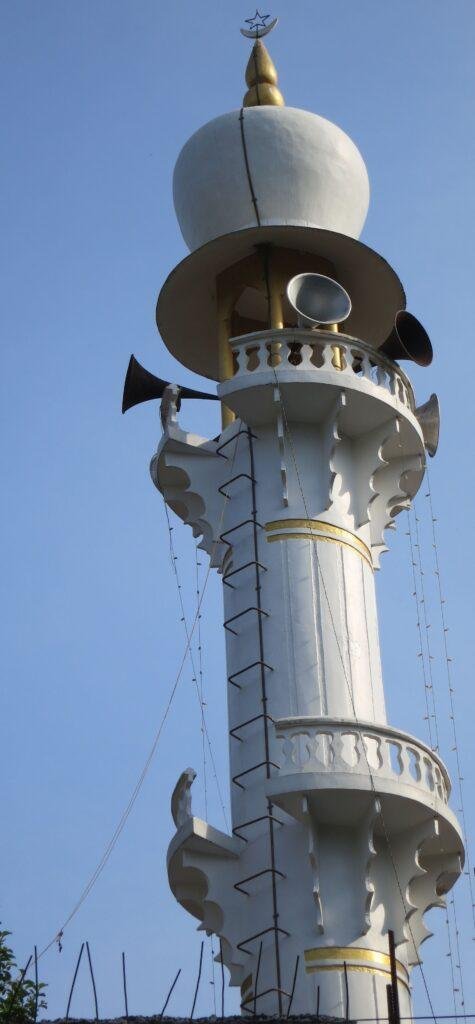

(A sampling of our lightning protection installations!)

The science is that aluminum is equally good as copper for protection from lightning except for use underground. Both Aluminum and Copper are approved by Underwriters Laboratories USA) for use in lightning protection. Our Minnalman LPS is a hybrid system that costs far less than and lasts just as long as a copper-only system. We also install all-copper.

A properly installed lightning protection system protects buildings and lives by channeling lightning strike energy in a safe and controlled manner to the earth termination network. Lightning protection system (LPS) has four parts:

A Rodhini LPS is the same system and the same components used in the USA.

Air terminals channel lightning strike current on to down conductors. There are two aspects to air terminals: (1) what kind they are and (2) where they are placed on a structure so that they will collectively protect the entire structure.

There are two kinds of air terminals used across the world:

Rodhini uses air terminals that are Franklin rods but with a slightly blunt tip as advocated by scientific research published in 2000, in the Journal of Geophysical Research, as having a greater chance of catching lightning strikes; these are now being increasingly used in the USA, Canada and China.

The non-conventional are of two kinds – early streamer emission (ESE) air terminals and charge transfer systems (CTS). ESE emits a charge stream early – hence the name – when quiescent charge conditions are detected in the cloud above. In this manner it is claimed that such a terminal can preferentially connect with a charge streamer – called a leader – coming down from the cloud and thus protect a large area of the structure. International Standard IEC 62305 has not yet approved this due to not having validation based on the physics. However, many of the tallest buildings in the world have ESE terminals. These terminals are said to produce charges of tens of KV at their tips and produce leaders in the presence of leaders from the clouds. Assuming this to be true, it is difficult for cheaper installations to achieve this. Moreover, the battery charge needs to be maintained with solar attachment or otherwise.

The supposed advantage of ESE air terminals is the coverage of a large area of the roof of a large building and its premises. However, the relatively high initial cost and periodic maintenance make ESE terminals impractical for homes and small buildings. Franklin rods are the best option in such cases. Moreover, Franklin rods generally require only an annual inspection for mechanical and electrical integrity. No battery failure to worry about!

CTS air terminals look like a crown of thick needles atop a mast. Proponents of CTS air terminals claim that ‘corona’ current emitted from their arrays of sharp points can help to neutralize some of the charge in the cloud above and thus prevent a strike. But field studies have not corroborated the claims. IE 62305 has not recommended CTS air terminals.

Having the right type of air terminal is not sufficient. They must have the right height and be placed on the right locations on the structure so as to protect every portion of the structure. RODHINI uses the well-known scientific method called the Rolling Sphere Method to compute the location and heights of the terminals. This is the same method used in NASA’s new strung-wire system – which is the same as a system with many Franklin rods – to protect launch pads.

Down conductors pass on the strike current to the Earth Electrode System. They must have low resistance and low self-inductance at the frequency of the lightning current. They can touch the wall or metal parts so that the building and the conductor will be at the same potential and no harm will be done to the wall or other materials in contact with it.

Equipotential Bonding: High voltage current passing through the down conductor of an LPS can create large electric potentials as compared to objects adjacent to it. This disparity can cause side jumps of charge, popularly known as ‘side flashes.’ So all metal bodies within 6 feet of the down conductor are connected using bonding jumpers to the down conductor. The earthing for house wiring is to be connected to the earthing of LPS through an equipotential bond. Likewise the live electric wires are to be bonded to the LPS earth through a Surge Protector.

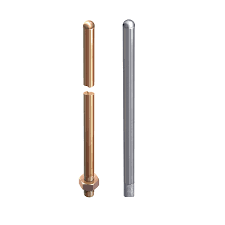

All-copper System: Rodhini uses round conductors that are either sold or woven. 20mmx3mm copper strip is also used. Rodhini manfactures stranded CU conductor (see the stranded conductor next to the solid round conductor in the picture). Inquiries are welcome.

Aluminum-copper System: Copper and aluminum are the metals to be used in lightning protection. Rodhini manufactures the aluminum components. Coupled with the copper underground, the total cost of the copper-aluminum LPS is about two-thirds of an all-copper system for houses and low-rise buildings. For highrises the cost is half that of copper. Rodhini is a pioneer in India in installing aluminum-copper LPS. Rodhini manufactures AL stranded conductor for wholesale. Inquiries are welcome.

This connects to the down conductor. Proper earthing is a must for the safe dispersal of the large amount of energy generated in a lightning-strike. Rodhini uses guidelines in IEC 62305 for earthing in different soil conditions. Accordingly, the system might be a single earth rod or multiple rods, earthing plates, meshes, earthing trench, or a combination of these to which the down conductor is connected.

The LPS installation and its components follow the guidelines of the lightning protection standard, IEC 62305.

IEC 62305 prescribes how to work with lightning to improve safety. LPS is not a do-it-yourself project. LPS should be installed by trained, experienced lightning protection specialists – the training of electricians does not include lightning protection system – in accordance with the national standard.

Rodhini LPS Pricing Formula shows itemized costs. It enables you to easily calculate LPS Total cost. This saves time because a fair price is obtained without having to negotiate price. Please study carefully; call if clarification is needed.

Total cost = Cost of (Materials + Design + Fabrication+ Transportation + Installation ) + margin

No GST

Materials: Air terminals, down conductor, earth rods, steel pipes, pvc pipes, junction box, pit covers, and fittings. (Customer may choose to provide the materials. )

Design (5% of Total Cost): Initial site visit testing resistivity of earth beside the building or structure, and engineering computation of layout and specifications of air terminals, down conductor, bondings, and earthing.

Fabrication (8% of Total Cost): Assembly of air terminal(s) and mounting mast(s)

Transportation: Transportation of materials, supervising staff and workers to and from site

Installation (18% of Total Cost): Engineering supervision of installation, on-site labor, use of machines, Argon welding, Exothermic welding, testing/commissioning, and 14-year warranty.

Margin: Margin is necessary for a service company to exist with its professional and technical staff and on-site workers so as to do scientifically correct installation. Margin can vary with the type of service industry, from below 20% to well above 20%. Our margin is 19% of total cost.

Note A. If the on-site labor required fewer workers and days than in the estimate, the installation cost will be reduced in the final invoice. If the on-site labor requires more workers and days, the final invoice will charge one-half the increased costs.

Note B. If the installation needs removal and re-fitting of ground tiles or/and roof ridges, then those costs (which are normally less than 6000) will be added to the net cost.

There are just six (6) steps.

Photos showing both roof and ground of the structure and structures or trees close/nearby are also taken.

Charge for the testing is Rs 1900 for distance of up to 60 kms from our (or installing affiliate’s) office. For distances above 60 kms, the charge is 2500. This testing charge is refunded if Rodhini installs the LPS. This charge ensures that customers are fair to Rodhini just as Rodhini is fair to customers.

Pricing of Surge Protection is also easily computed. It is installation cost of Rs 3000 plus cost of SPD as per invoice from Manufacturer of SPD. The SPD's we have installed are from Schneider Electric and ABB. (Rodhini Safety installs SPD only for its LPS customers.)